Post‑T&CM 2025 Reflections: takeaways that shaped our approach

At the recent Telematics & Connected Mobility conference, the second day featured multiple talks on Bluetooth Low Energy (BLE), including an excellent session from Teltonika on using anchors for indoor positioning. Those talks sparked active hallway discussions about where BLE fits, how to implement it, and how to move from proof‑of‑concepts to production.

Our key takeaways:

-

The community’s interest in BLE is high.

-

Many use cases discussed are still at the “idea” stage—TSPs and end users are still evaluating this field and operational fit.

-

Production deployments exist but are often local and tailored. One hands‑on example presented at the event: a BLE‑driven agricultural app by Jan Palas (AG Info), focused on extending automation and improving report precision.

This article turns those insights into a concrete, shippable scenario you can deploy with Tags by GPS‑Trace today.

Problem we’re solving

After reviewing several public reports and news articles, it becomes clearer: equipment and tool theft is not a local problem, but a global one. Whether in Europe, North America, or Australia, the numbers are consistent: items, tools, machinery get forgotten on sites, mixed between jobs, or quietly disappear far more frequently than might initially appear.

- According to the European Rental Association (ERA), the combined annual losses from theft and vandalism in the European rental, construction, and agricultural sectors are estimated at around €1.5 billion per year.

-

In the rental industry, equipment theft is estimated at ~$100M per year, with >360 pieces reported stolen each month (America Rental Association).

-

In the UK alone, there were 25,525 police‑reported tool theft cases in 2024 (about one every 21 minutes), valued at ~£40M. Nearly half of all thefts were from vehicles.

- In Victoria(Australia), more than A$33 million worth of tools were stolen in 2023 — including 18,626 power tools and 14,911 hand tools, according to the Crime Statistics Agency. In Queensland(Australia), police reported police reported more than 25,000 stolen tools in the 2024–25 financial year and launched a prevention campaign to combat the surge.

-

Earlier data from Aviva Canada put annual industry losses at roughly C$46 million, including C$15–20 million in Ontario alone, highlighting the concentration of theft around large industrial regions.

Takeaway: Worldwide, theft of tools and heavy equipment is no longer a marginal issue — it’s a systemic operational risk that costs the industry hundreds of millions each year and drives demand for affordable asset-tracking solutions such as BLE-based monitoring.

What to tag first (high‑loss categories)

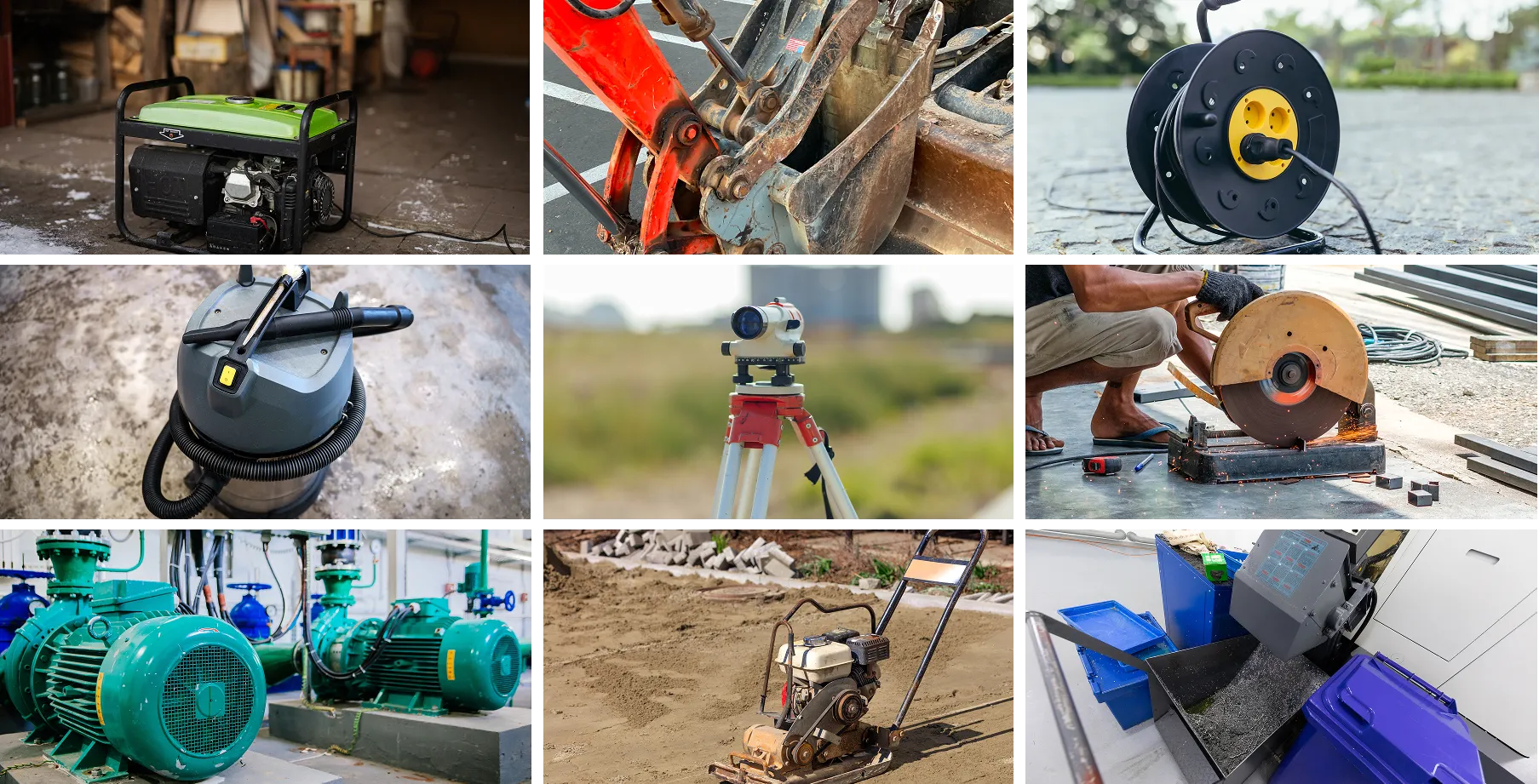

From rental partners and field audits, the usual suspects are small, portable, and easy to misplace or “reallocate”: generators (2–6 kW), plate compactors, cut‑off saws, pumps, portable welders, laser levels & tripods, industrial vacuums, extension reels, accessories, and attachments for mini‑equipment (buckets, forks, breakers). These items are valuable, mobile, and frequently changing hands—prime candidates for BLE tagging.

(Generators, plate compactors, cut‑off saws, pumps, portable welders, laser levels & tripods, industrial vacuums, extension reels, accessories, and attachments for mini‑equipment (buckets, forks, breakers) that can be safe with BLE beacons)

(Generators, plate compactors, cut‑off saws, pumps, portable welders, laser levels & tripods, industrial vacuums, extension reels, accessories, and attachments for mini‑equipment (buckets, forks, breakers) that can be safe with BLE beacons)

But the thefts themselves are only part of the story.

The real costs go far beyond the stolen item — they include operational downtime, delays in project schedules, and the logistical overhead of sourcing replacements, reassigning equipment, and managing unexpected gaps in fleet availability. Each missing generator or misplaced laser level sets off a small chain reaction: extra paperwork, calls between teams, temporary rentals, and lost work hours. When multiplied across dozens of assets and sites, these indirect losses often outweigh the value of the stolen tool itself. Trust me, i have a degree in logistics :)

The scenario: “Drive‑by discovery” for rental and equipment control

Putting a "full package" with GPS device and SIM on every drill, laser, or generator is rarely economical. BLE tags/beacons are the right middle ground: inexpensive, long‑lived, and discoverable by gateways you already own (vehicles, routers, mobile apps). In Tags, those gateways become your eyes and ears, emitting “last‑seen” updates for each tagged asset.

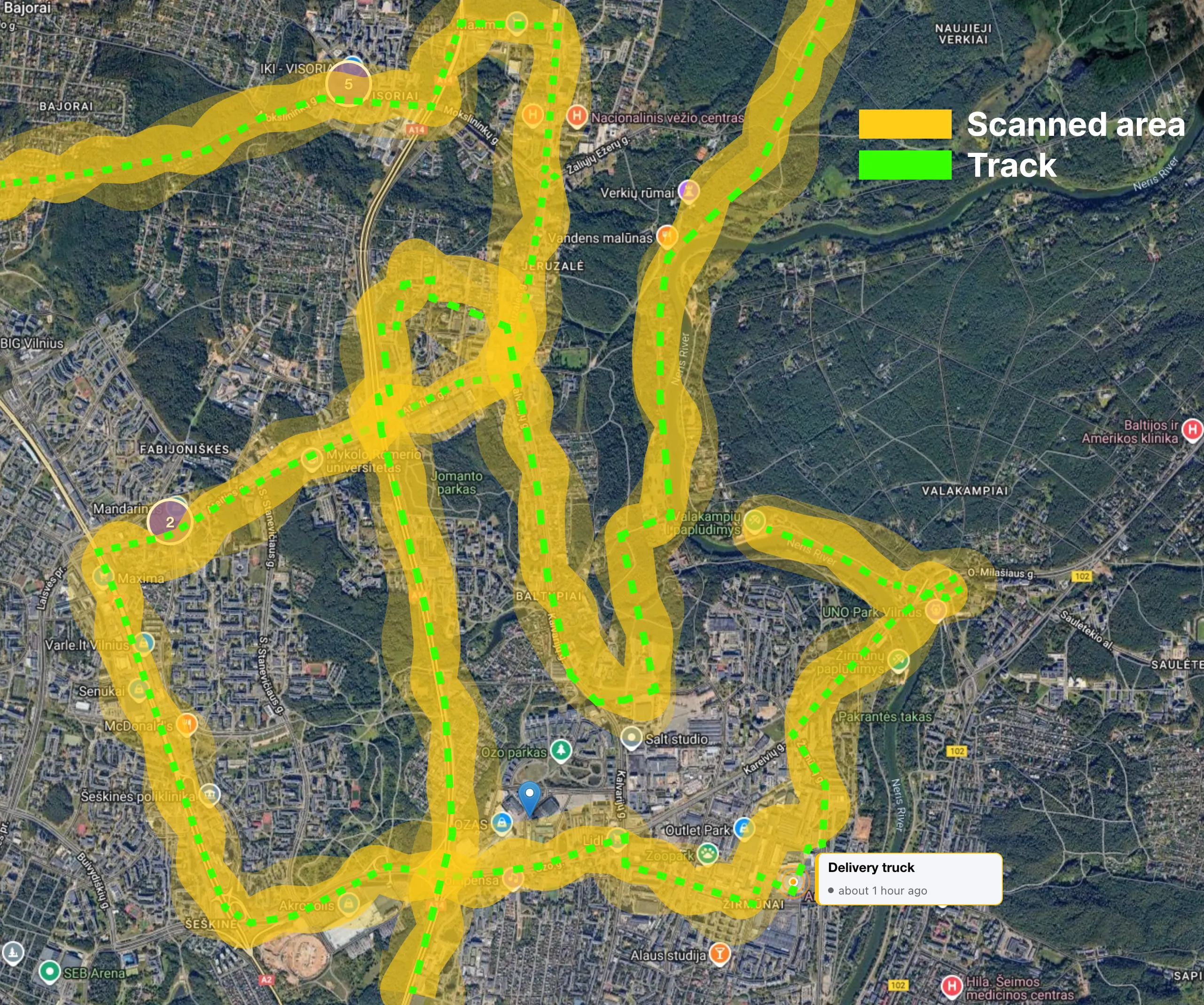

Scenario: attach a BLE beacon to each rental item. Vehicles already fitted with trackers scan for nearby beacons while driving past sites, loading bays, and yards. The tracker sends “who I saw, when, where, and how strong the signal was” to the platform. Tags by GPS‑Trace turns that stream into:

-

“Last seen” map per asset

-

Automatic association of assets with vehicles/locations

-

Alerts (“asset left at jobsite”, “not seen in X hours”, “on exit gate but not in order”)

-

Evidence for billing/returns (which vehicle took what, and when)

Why it works: BLE beacons are designed to advertise frequently at low power, and tracking devices can scan continuously or in short, repeating windows—so a truck passing within range has a high chance of seeing the tag at least once. Let's call it Discovery or Scanning.

(Here’s an visual example using just 2 trucks with a GPS tracker that supports BLE around scanning)

(Here’s an visual example using just 2 trucks with a GPS tracker that supports BLE around scanning)

How discovery/scanning works (and Why Timing Matters)

BLE discovery is all about timing.

Beacons periodically broadcast short signals (“advertising”), while scanners (trackers, gateways, phones) listen in defined windows.

A tag is detected only when these two actions overlap in time — when the beacon transmits while the scanner is listening.

Beacon Advertising

Each beacon sends a message every few milliseconds or seconds — this is the advertising interval.

-

Common range: 100 ms–1 s for fast detection.

-

Allowed range: 20 ms–10.24 s (BLE standard).

Shorter intervals = faster discovery, higher battery drain.

Scanning

Scanners listen in windows defined by two settings:

Example: The scanner rests for 30 seconds, then listens for 10 seconds, and repeats this cycle continuously.

During each 40-second cycle, it’s active for about one-quarter of the time.

This setup provides a good balance between detection reliability and power efficiency, while continuous (non-stop) scanning remains the most reliable option when sufficient power is available.

Possible setups:

| Scenario |

Beacon Advertising Interval |

Scan Duration |

Update Frequency |

Notes |

| Fast discovery (drive-by) |

300-500 ms |

15–20 s |

20–30 s |

Ideal for moving vehicles, stable power |

| Balanced (fleet use) |

500–1500 ms |

10–20 s |

30–40 s |

Good compromise between detection and power |

| Battery-saving (static use) |

2–5 s |

10 s |

60 s |

For low-power gateways or long-life tags |

Detection Range

Typical BLE range is 60–80 meters in open space, but around metal structures, vehicles, or concrete walls it drops significantly. Reliable systems usually confirm presence only after multiple detections or by using an RSSI threshold to filter weak signals.

In practice, such interference is most common in warehouses, garages, and covered areas — situations where fixed gateways or BLE-enabled routers can complement mobile scanners and provide stable detection coverage.

Getting Started: What You Need to Make It Work

To set up BLE-based tracking, you only need three layers working together:

beacons, gateways, and a Tags app to visualize what’s going on.

Hardware Layer

BLE tags or beacons

Small wireless devices that broadcast their ID every few seconds or milliseconds.

Choose beacons with a decent range (60–80 m), IP67 protection, and a battery life that fits your use case (from a year up to ten, depending on how often they advertise).

Examples include industrial BLE beacons like EYE Beacon (BTSID1), but any standard BLE 4.2+ device will do.

Gateways in Motion

Check whether the GPS trackers in your fleet support BLE scanning — not all do.

Even among compatible models, scan frequency and configuration options differ.

If BLE is supported, your vehicles can act as mobile gateways, detecting nearby tags as they move.

Trackers can scan continuously or in short cycles — for example, listen for 10 s, rest for 30 s. Manufacturers offering BLE-capable trackers include

Teltonika, Ruptela, Atrack, Queclink, and Digital Matter.

If your current devices aren’t BLE-enabled, adding a few compatible models or external BLE gateways is usually enough to start capturing data across your operations.

Stationary gateways (optional)

Install a few stationary readers — routers or mobile GPS devices with BLE capabilities — at yard gates or warehouse entrances.

They catch tags entering or leaving the area and forward this data to our flespi backend.

These gateways provide a safety net that complements what your vehicles already capture.

Software Layer

Once your gateways start reporting what they see Tags by GPS-Trace — does the rest:

From here you can see: see a last-seen map, check geofence presence reports, label your assets and much more. More about Tags app features in our special topic. --> Tags: first steps in Asset tracking field .

Test&Tune

Getting started with Tags is easy.

Just sign up in the Partner Panel and activate your free 30-day trial.

Once the trial is active, you can create gateways and connect them to the system.

As soon as your gateways detect BLE tags, you’ll be able to turn them into assets inside the app.

Detailed onboarding and documentation are also available directly in the Partner Panel.

Place your gateways where it makes sense — on vehicles, at warehouse gates, or on fixed sites — and you’re good to go.

If you have any questions, just ask Tracy, our AI assistant, right in the Partner Panel — or drop us a quick message in the same chat. See you!